40′ POULTRY PLANT IN A BOX®

OUR FLAGSHIP POULTRY PROCESSING EQUIPMENT UNIT

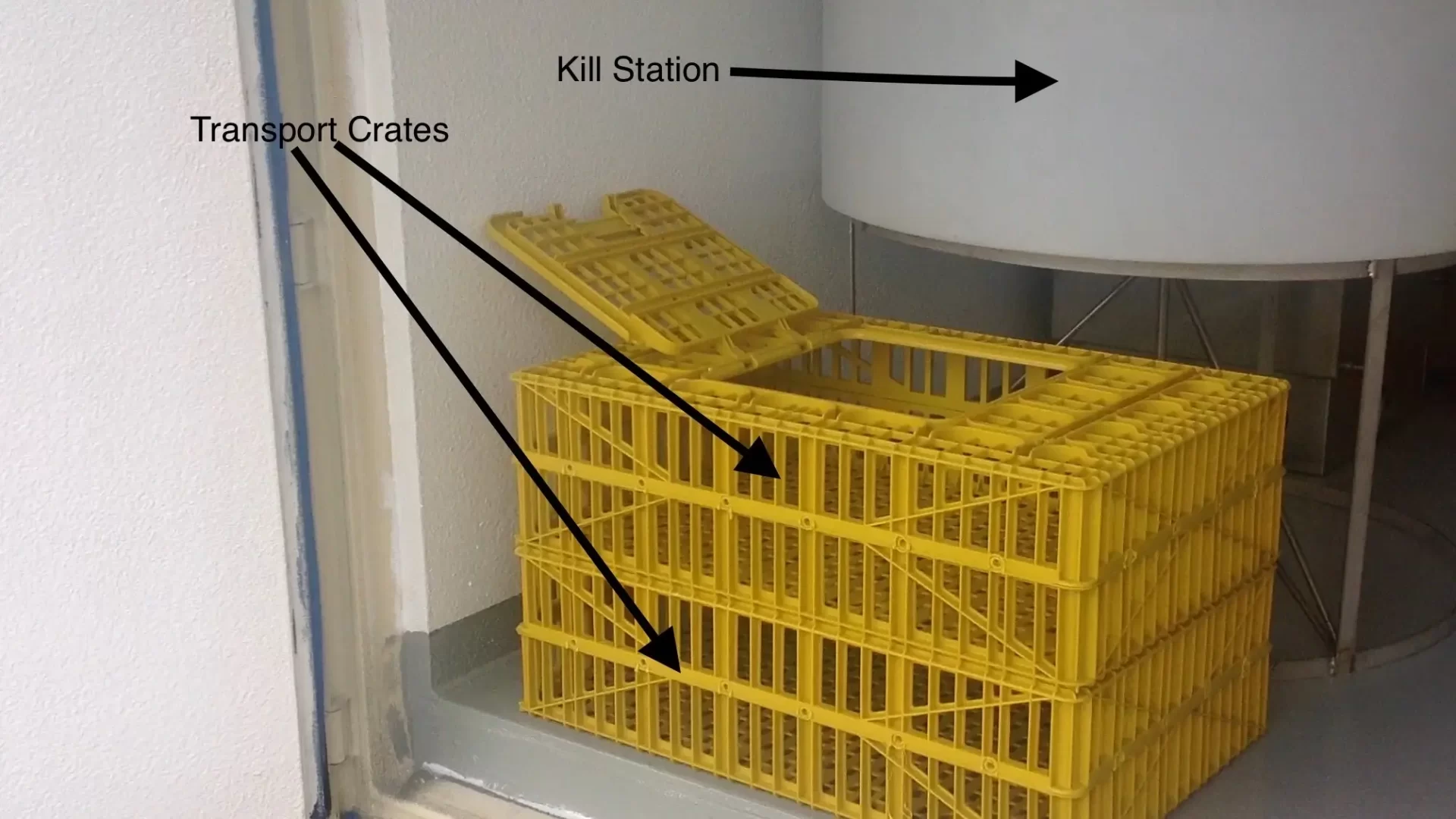

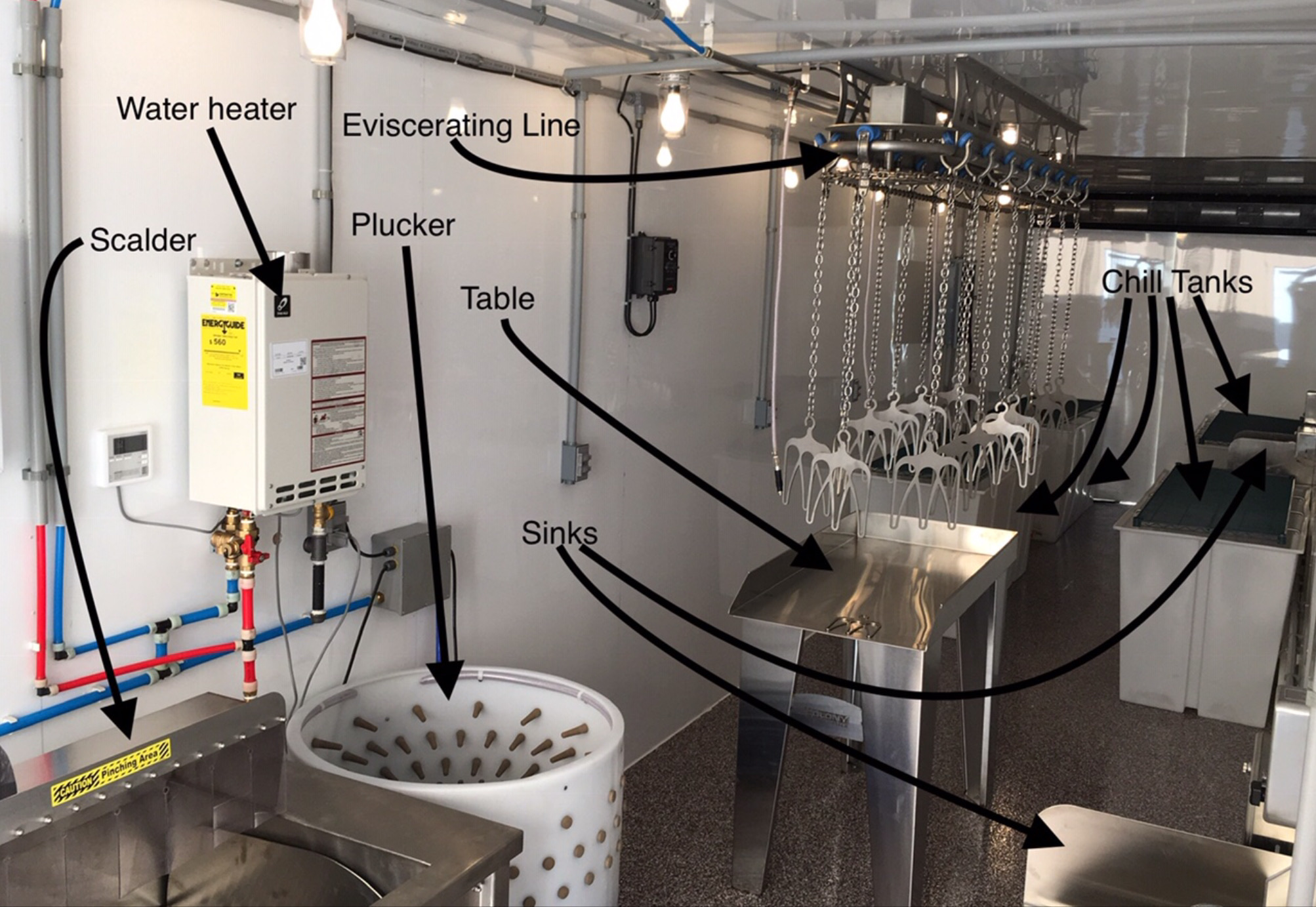

Our original flagship model, the Poultry Plant in a Box®, is designed for efficiency and durability. It includes a complete lineup of poultry processing equipment, arranged in process flow order: an 18-cone rotary kill station, Scalder XL, on-demand 180°F propane water heater, Plucker XL with foot switch, and a heavy stainless steel catch table. The unit features an overhead variable-speed evisceration line with 18 stainless steel shackles, a mini-split heating/cooling system, and a double 48-inch man door with windows. Interior highlights include two stainless steel sinks, glued and riveted 18-gauge aluminum white walls and ceiling, R-19 insulation throughout, and a food-grade epoxy floor. Additional components include a full-width twin-motor air curtain, 100-amp electric panel, LP gas, water entrances, stainless steel plumbing offsets, PEX water lines, six overhead one-hand water nozzles, and LED lighting—all housed in a 9′ x 40′ container rated for processing up to 200 birds per hour.

THE BOX

Shipping containers, originally manufactured in the Pacific Rim, are designed for durability and efficiency. These containers, typically 40′ long and 9′ high, are used to transport export goods across the globe, stacked up to eight high on massive ocean freighters. Their corrugated metal shells provide exceptional strength, making them highly transportable, stackable, and cost-effective. For our units, we use ‘one-trippers,’ containers that are like new, ensuring quality and reliability for housing your poultry processing equipment.

Please note, site preparation, rinse water disposal, utilities hookup, and container offloading are not included in the base price. Prices are subject to change based on market conditions and customization needs.

EFFICIENCY

Because of minimal worker steps, doubled cone/scald capacity, and an evisceration rail running down the middle, our design and space allow for maximum equipment utilization with up to eight workers. Equipment capacity is 8-9 birds per minute, nearly 500 birds per hour. Peak human performance measured thus far on our scale is 48 birds per person per hour. With five experienced operators the PIB can process 200 birds per hour.

ECONOMICS

Three Man Team – Five hour process

Hourly return @ $3/bird x 120 birds = $360

Labor costs @ $20/hr = $60

Gross Net = $300/hr, $1,500/day

Five Man Team – Five hour process

Hourly return @ $3/bird x 200 birds = $600

Labor costs @ $20/hr = $100

Gross Net = $500/hr, $2,500/day

FIve Man Team – Eight hour process

Hourly return @ $3/bird x 200 birds = $600

Labor costs @ $20/hr = $100

Gross Net = $500/hr, $4,000/day

WHAT’S INCLUDED

40′ POULTRY

Standard Poultry Plant in a Box® unit includes:

- 18-Cone Rotary Kill Station

- Scalder XL

- On-demand 180F propane water heater

- Plucker XL and foot switch

- Heavy SS catch table

- Overhead variable speed evisceration line with 18 SS shackles

- Mini-Split heating/cooling unit

- Double 48″ man door with windows

- two SS sinks

- 18 ga. Aluminum white ceiling and walls, glued and riveted R-19 insulation throughout

- Food grade epoxy floor

- full width twin-motor air curtain

- 100 Amp electric panel

- House electrical entrance

- LP gas entrance

- water entrance

- SS plumbing offsets

- all PEX water lines

- six overhead one-hand water nozzles

- LED lighting

REQUEST A QUOTE

UPGRADES & ADD-ONS

Select Add-ons below to be included in your quote

BOX UPGRADES

EQUIPMENT

SERVICES